Build Manufacturing Systems That Work in Harmony, Not Silos

Consolidate disparate systems into composable apps with low-code/no-code

Trying to Solve Any of These Challenges?

Slow time-to-develop

Pen and paper based approvals

Multiple siloed systems

Rigid ERP systems

Crumbling legacy systems

Mounting technical debt

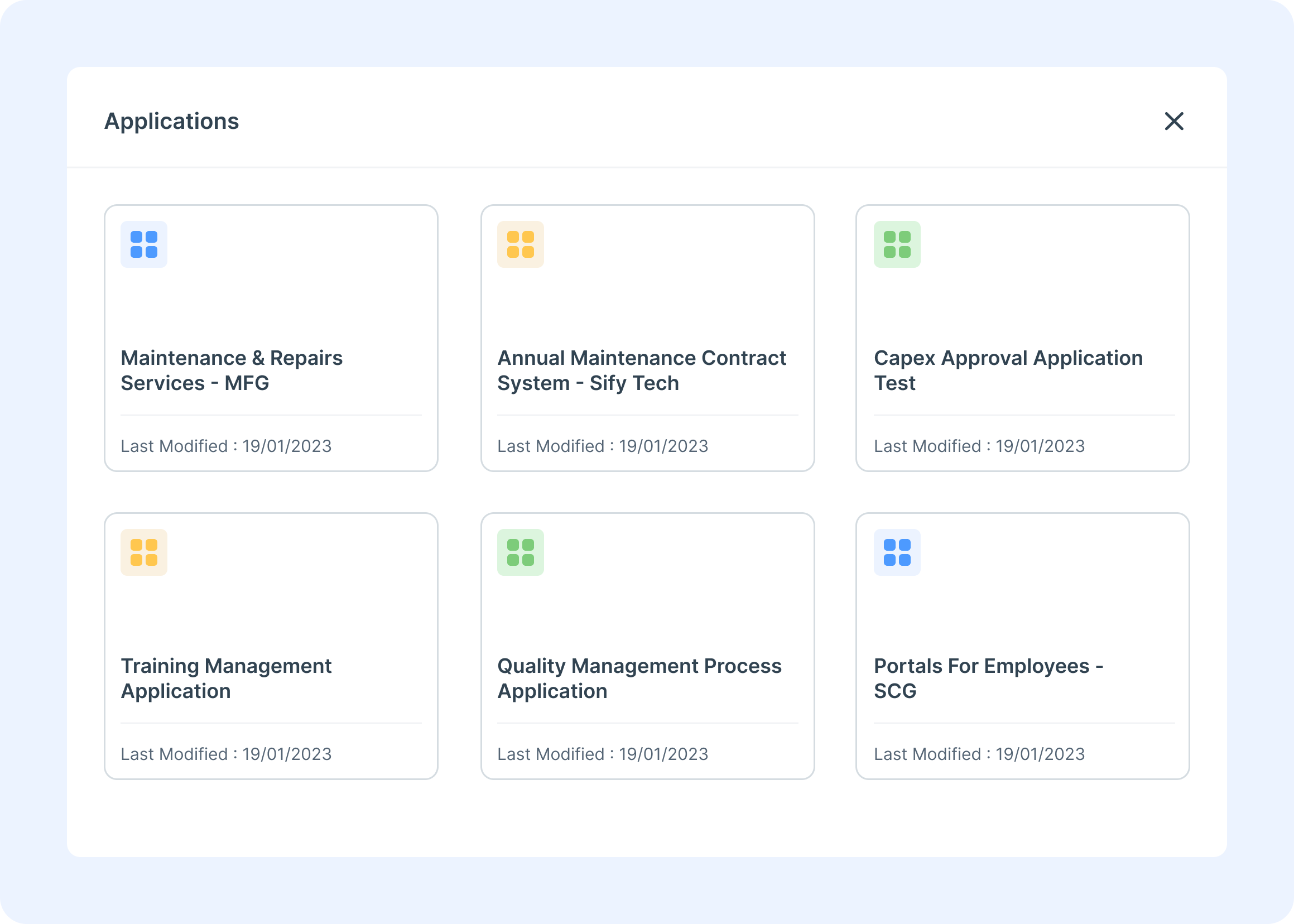

From Pen and Paper to Custom

Manufacturing Apps

Vendor Onboarding

Manage supplier information, including contact details, pricing agreements, and performance history. Facilitate efficient communication with suppliers and enable evaluation and selection of reliable vendors through automated workflows.

Material Requirement Planning

Integrate with production planning systems to generate material requirements based on production schedules. Automate the creation of purchase orders or internal material transfers to ensure timely availability of materials for production.

Order Management

Automate the creation, tracking, and management of purchase orders. Allow users to generate and send purchase orders to suppliers, track order status, and manage order revisions and cancellations.

Transportation Management

Build applications that give you visibility into shipment planning, route optimization, tracking updates, and integrate it with your ERP system seamlessly.

Material Replenishment

Automate the material replenishment process, including stock monitoring, automated reorder point calculations, generating purchase requisitions, and triggering notifications to suppliers or internal departments for material restocking.

Change Management

Automate the change management process for product revisions, process improvements, or engineering changes. Include steps such as change request submission, review and approval, impact analysis, implementation planning, and communication to stakeholders.

Inventory Management

Manage inventory levels and automate the fulfillment process. Integrate with inventory systems to track replacement parts and ensure availability for warranty repairs.

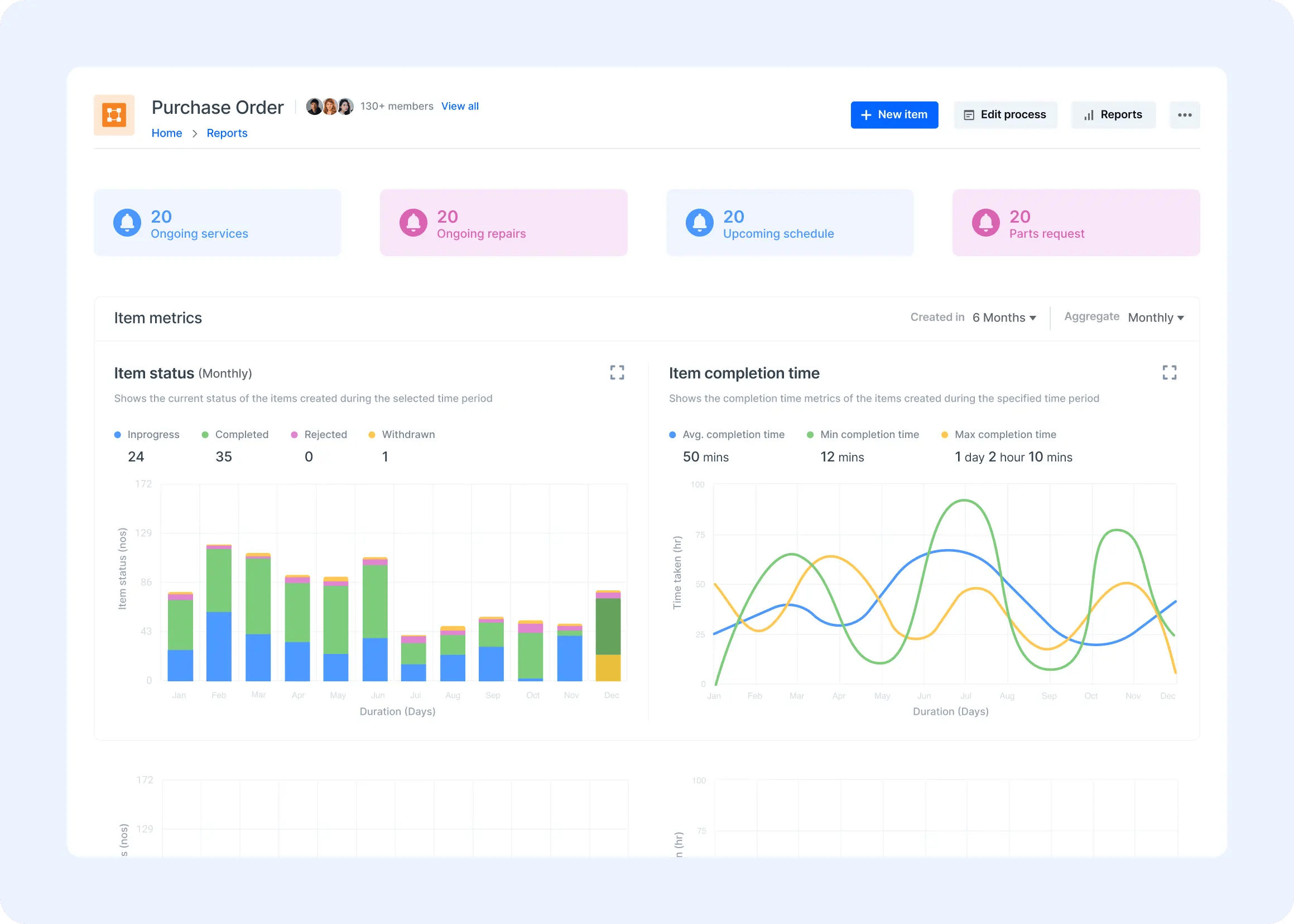

Production Reporting

Capture real-time data from manufacturing systems, analyze production metrics, generate reports or dashboards, and share them with relevant stakeholders for better decision-making.

Generate ASN

Maintain an ASN document that contains detailed information about the shipment. Include details such as the purchase order number, shipment date, carrier information, item details (SKU, quantity, and descriptions), packaging details, and any additional information required by the trading partner or customer.

Export Control & Documentation

Implement an automated screening system that checks the product, destination, end-user, and identify any potential export compliance risks associated with the transaction. Generate the necessary reports of commercial invoices, bill of lading, and export declarations.

Customer Returns & Complaints

Enable customers to submit their return or complaint requests through online forms, or customer service portals. Assign tickets to relevant team, generate unique case number, trigger an automated customer feedback survey, and send out acknowledgement emails based on trigger conditions.

Warranty Management

Allow customers to register and claim their product warranties digitally. Compare the claim details against warranty terms, product information, and customer records to ensure the claim is valid on a single interface. Generate reports on warranty claims, including metrics such as claim volumes, resolution times, cost analysis, and customer satisfaction.

Credit Check

Build workflows to analyze the credit information retrieved from external sources by automatically applying internal credit policies to determine the creditworthiness of customers.

Order to Cash

Automate the order processing and revenue collection process. Include steps such as order entry, credit check, order fulfillment, invoicing, payment receipt, and revenue recognition.

Fixed Asset Management

Streamline the tracking and management of fixed assets by automating asset acquisition, depreciation calculation, maintenance scheduling, disposal, and retirement. Ensure accurate recording of asset details, depreciation calculations, and gain visibility into asset status and valuation.

LC & Bill of Guarantee

Verify documents, check compliance, and automatically generate the LC or Bill of Guarantee document based on the provided information post approval from relevant stakeholders. Automate the amendment request, review, and approval steps, ensuring proper documentation and compliance.

Maintainance Requisition

Enable employees or equipment operators to submit maintenance requests electronically via a web portal or mobile app. Automatically validate the maintenance request, checking for completeness and accuracy.

Quality Control

Define inspection criteria, capturing inspection data electronically, triggering alerts for non-conforming products, and routing them for further analysis or corrective action.

Periodic Maintenance

Automate the maintenance and servicing of manufacturing equipment. Schedule preventive maintenance tasks, track equipment performance, capture maintenance history, and generate work orders for maintenance personnel.

Repair and Maintainance

Manage the entire repair and replacement process for warranty claims. Track the status of each claim, schedules repairs or replacements, assigns tasks to technicians, and gain real-time visibility into the progress of each case.

Employee Onboarding

Create and manage digital documents, and enable self-service for new hires to complete onboarding work. Integrate with HR systems, such as payroll and benefits platforms, to ensure data accuracy across systems.

Employee Offboarding

Build workflows and checklists to guide HR and managers through the process of employee departures. Collect feedback through exit interviews and surveys to gain insights into the reasons for employee departures.

Timesheet Management

Easily track hours worked, overtime, and paid time off. Automatically calculate time-based wages and generate detailed reports for efficient payroll processing.

Performance Management

Automate goal setting, performance appraisals and feedback processes to ensure timely completion by relevant stakeholders.

Get a free list of all the manufacturing apps you can build

Download the Manufacturing Use Cases List

Transform your internal operations with the right manufacturing apps

Modernize and Digitize Operations End-to-End

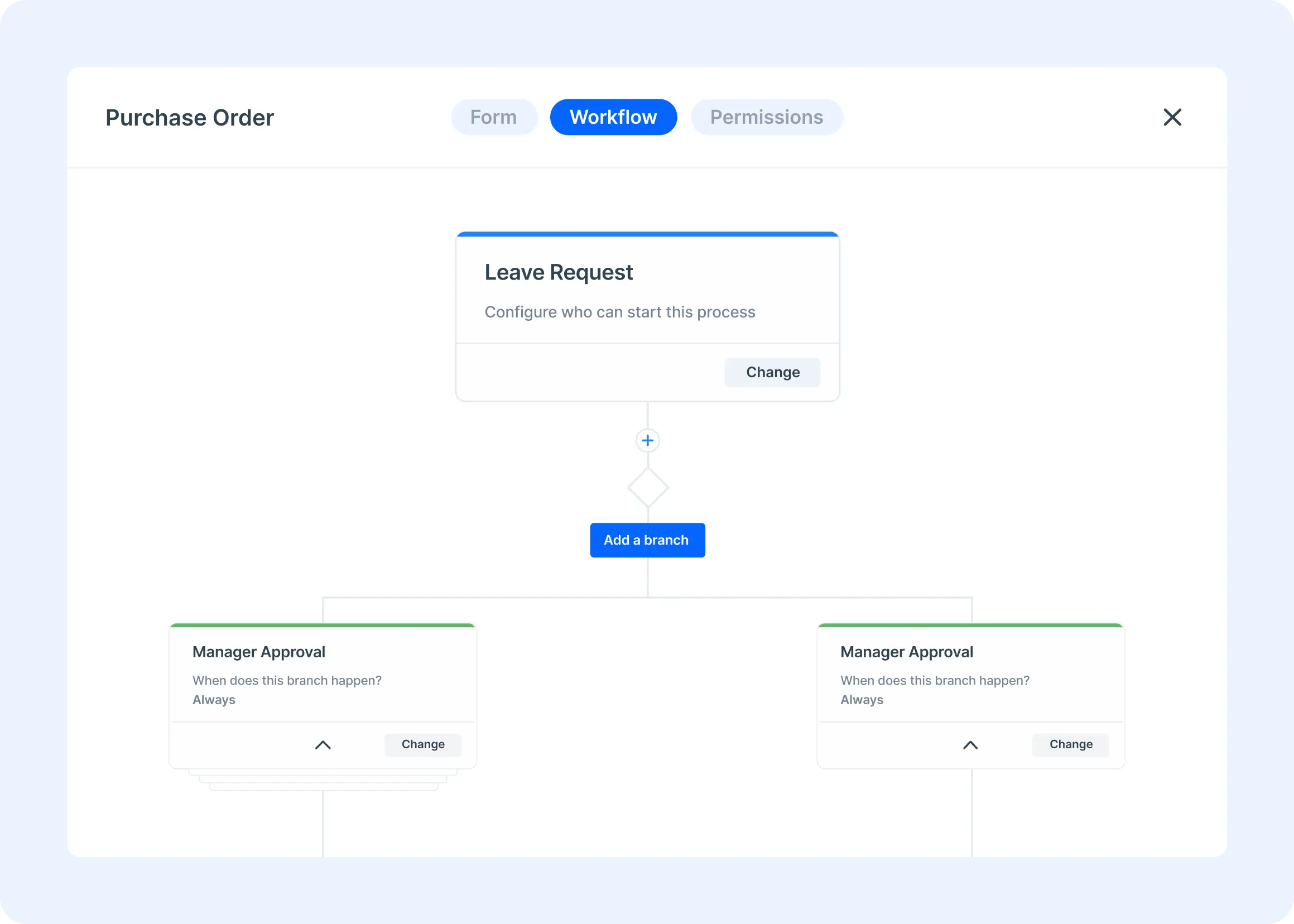

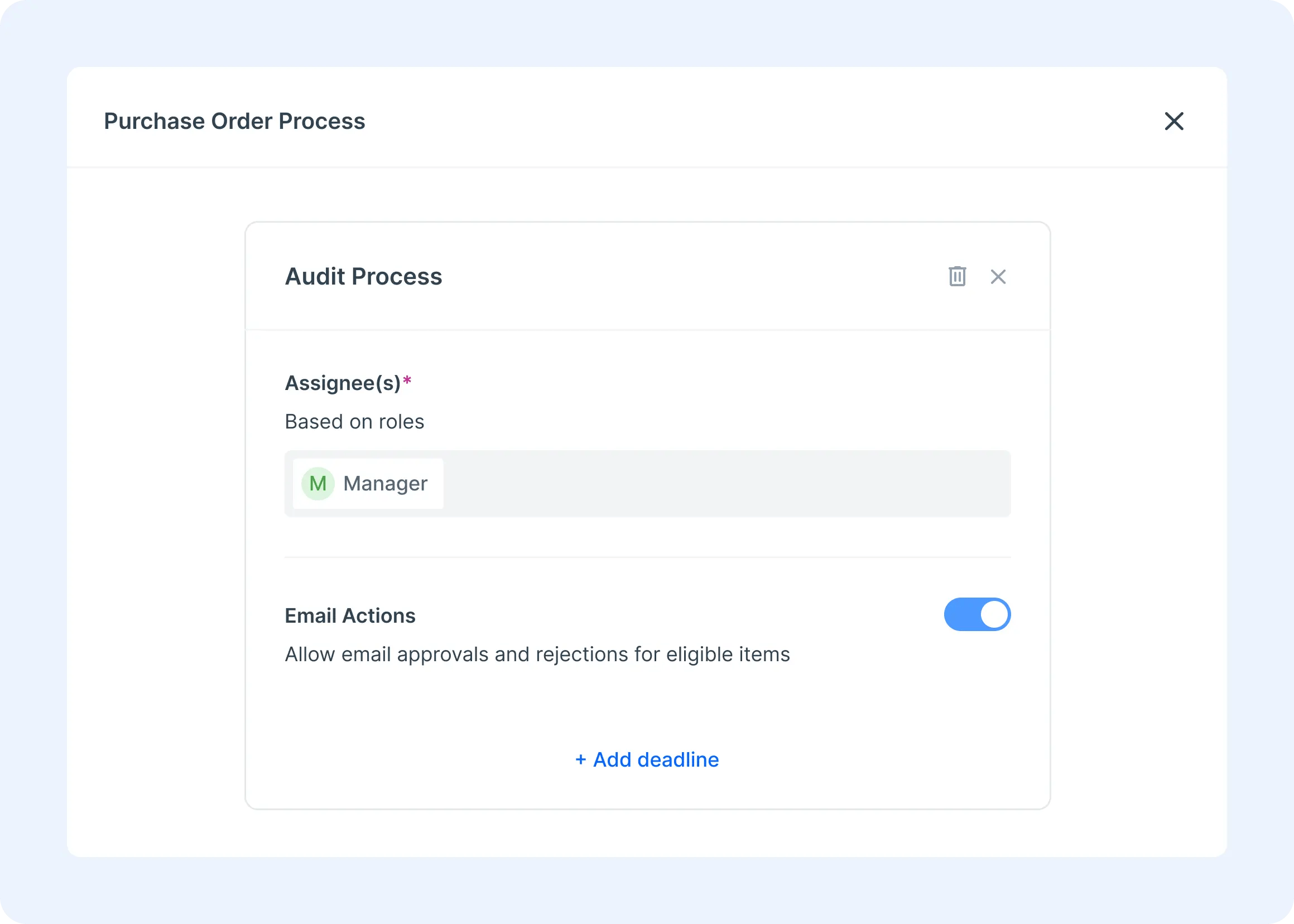

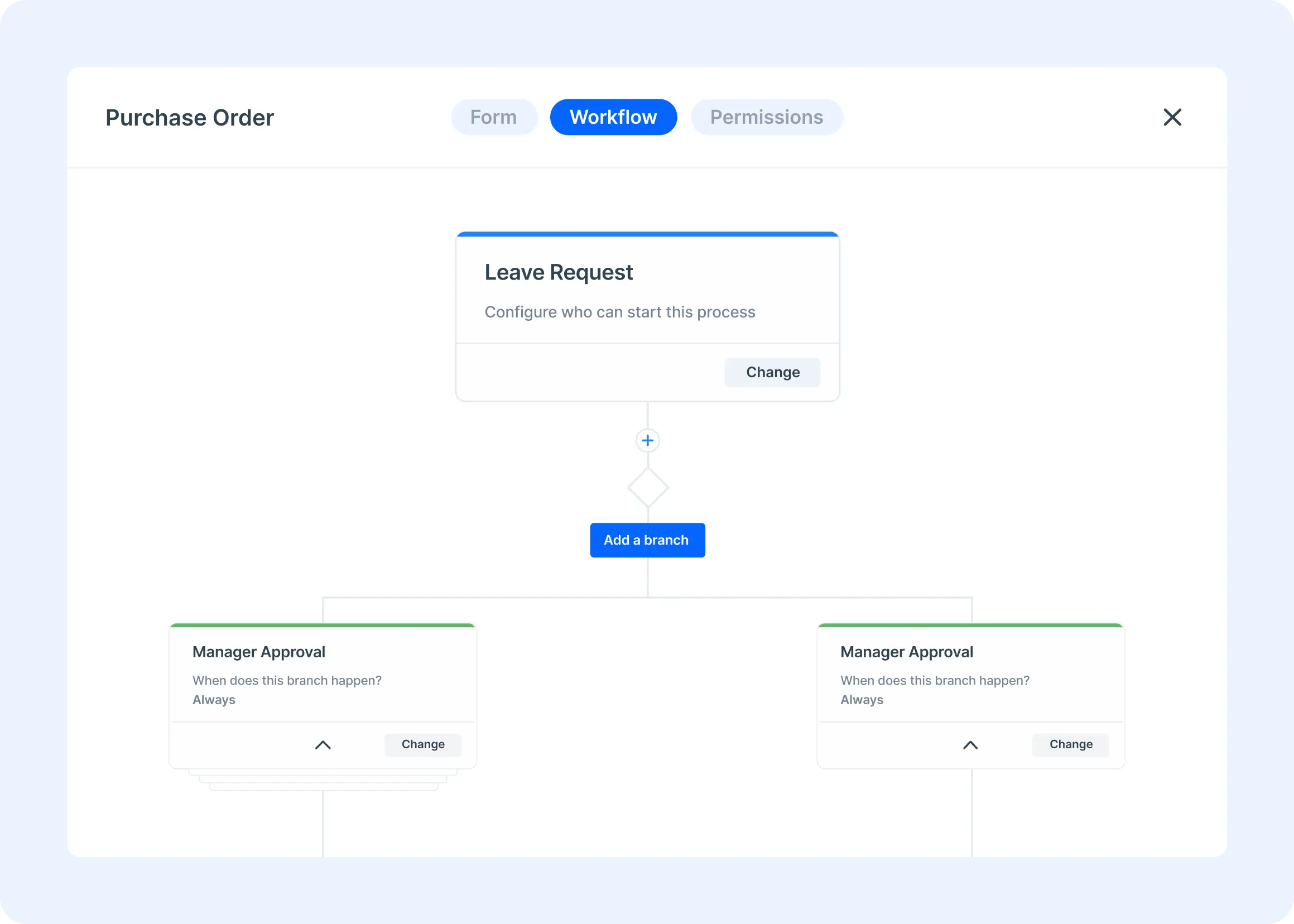

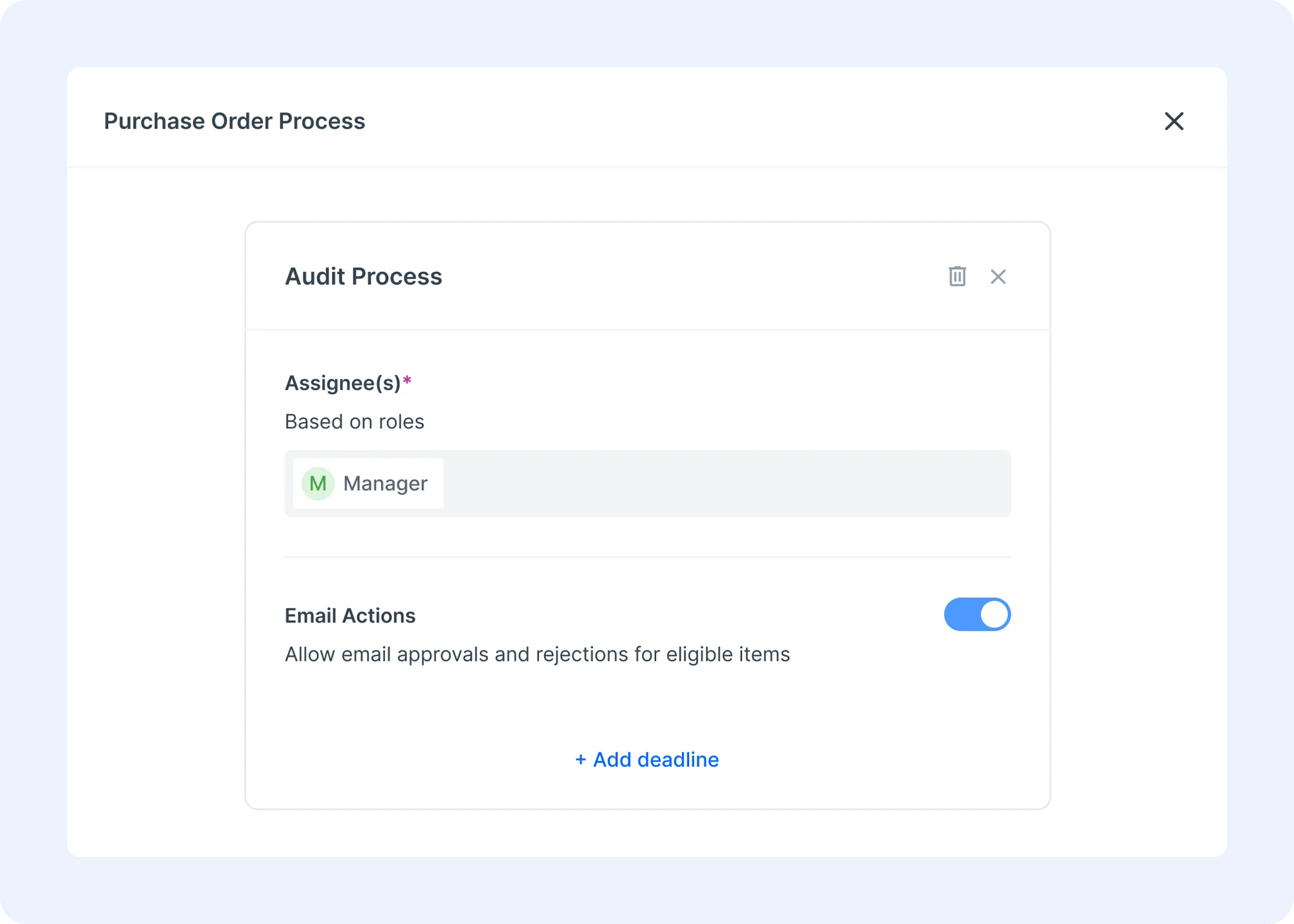

Automate Follow Ups

Configure rule-based workflows to include the right person at the right time

Trigger Specific Actions

Automate emails, enable barcode scanners, track geo locations, build checklists, and more

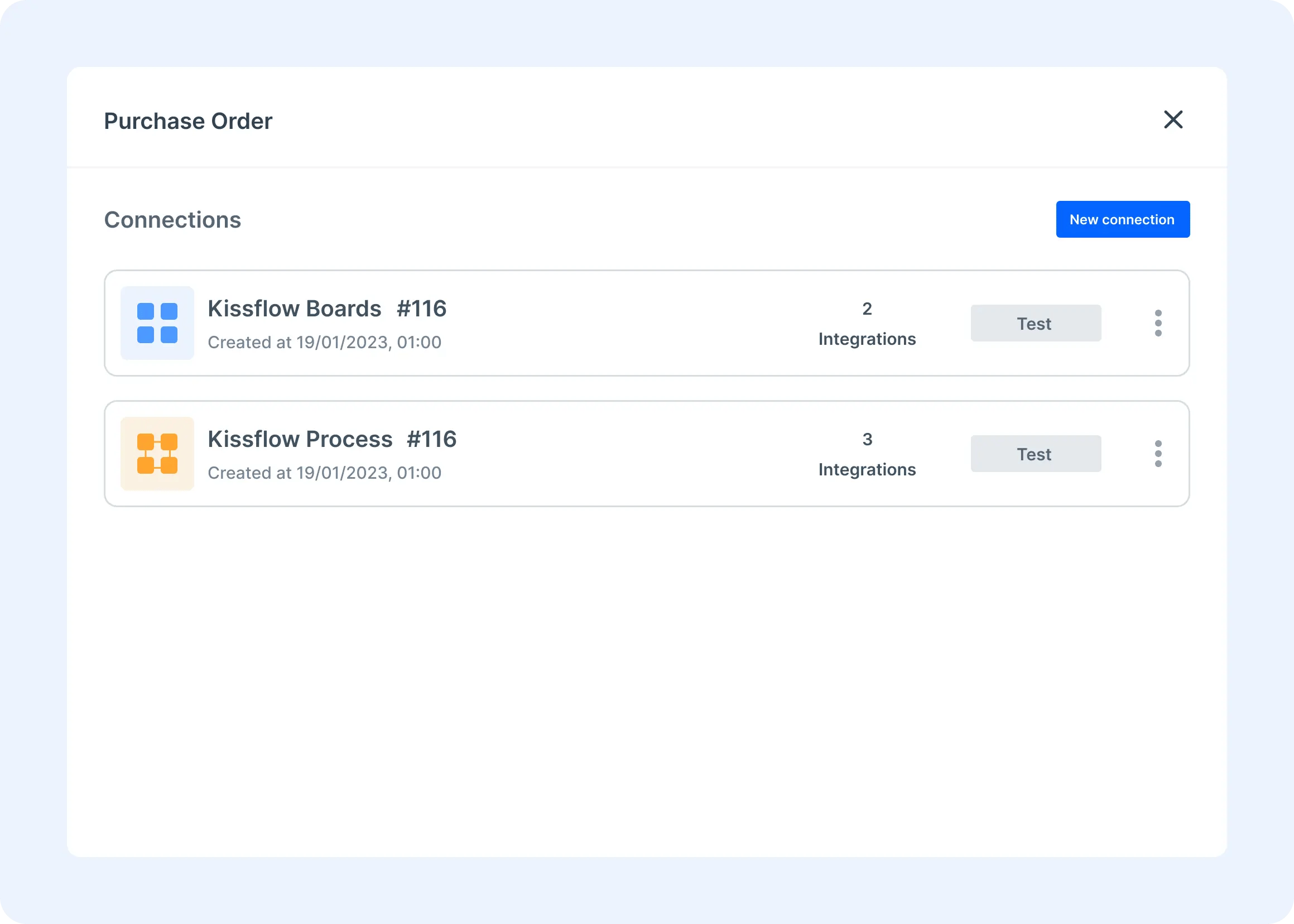

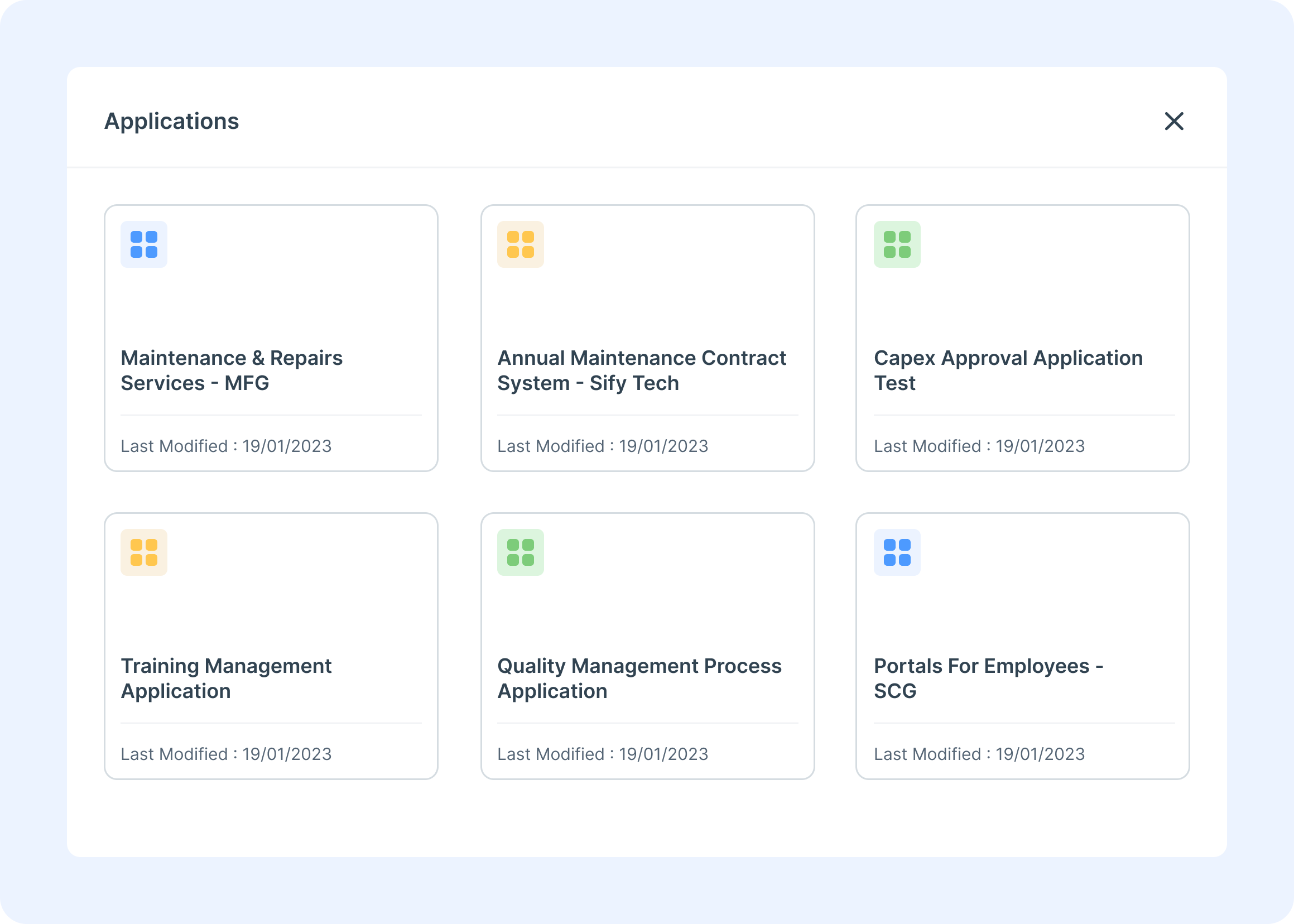

Unify Siloed Processes

Consolidate disparate processes into a unified system through low-code automation

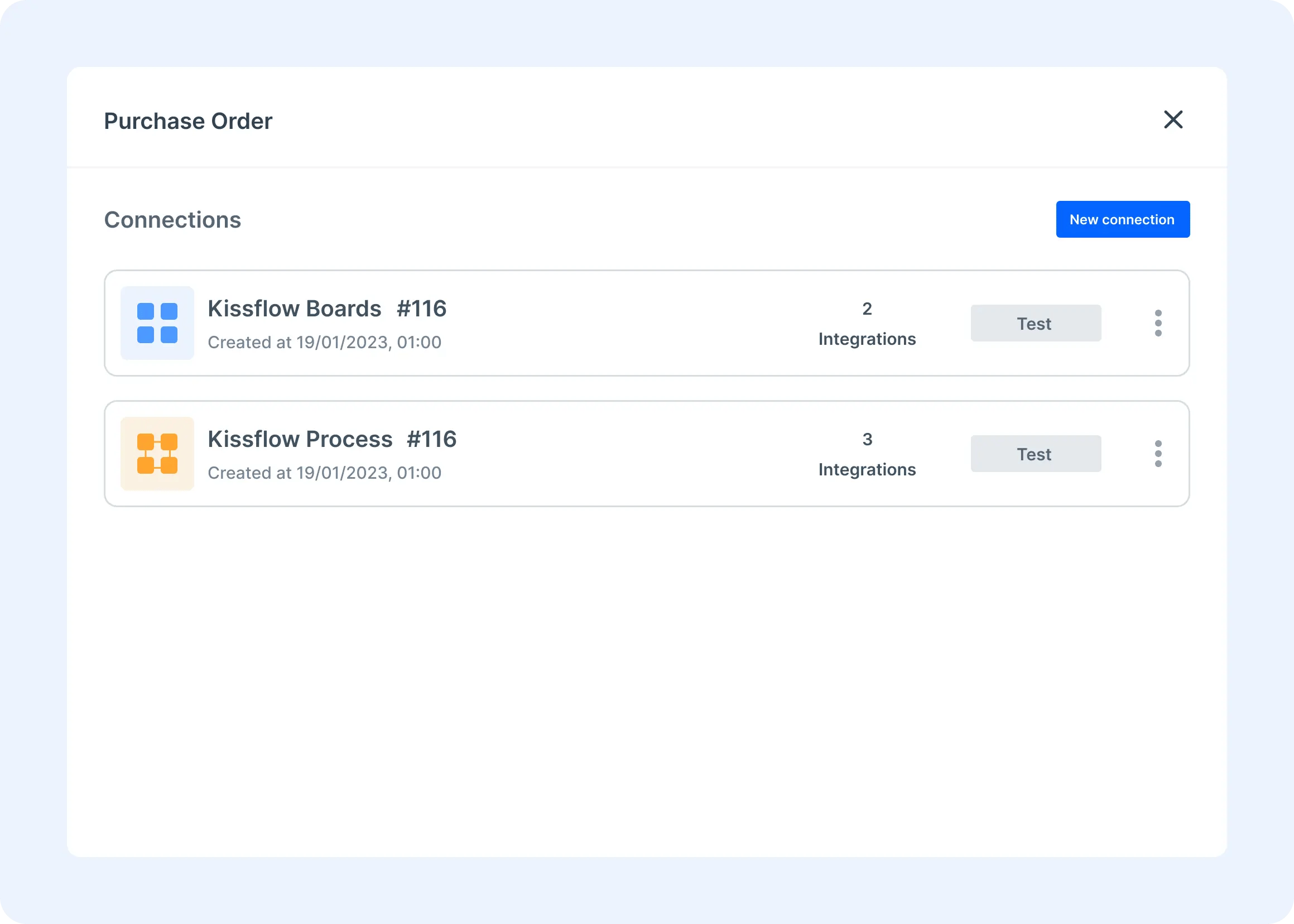

Orchestrate Master Data

Connect and update data across multiple frontend and backend systems automatically

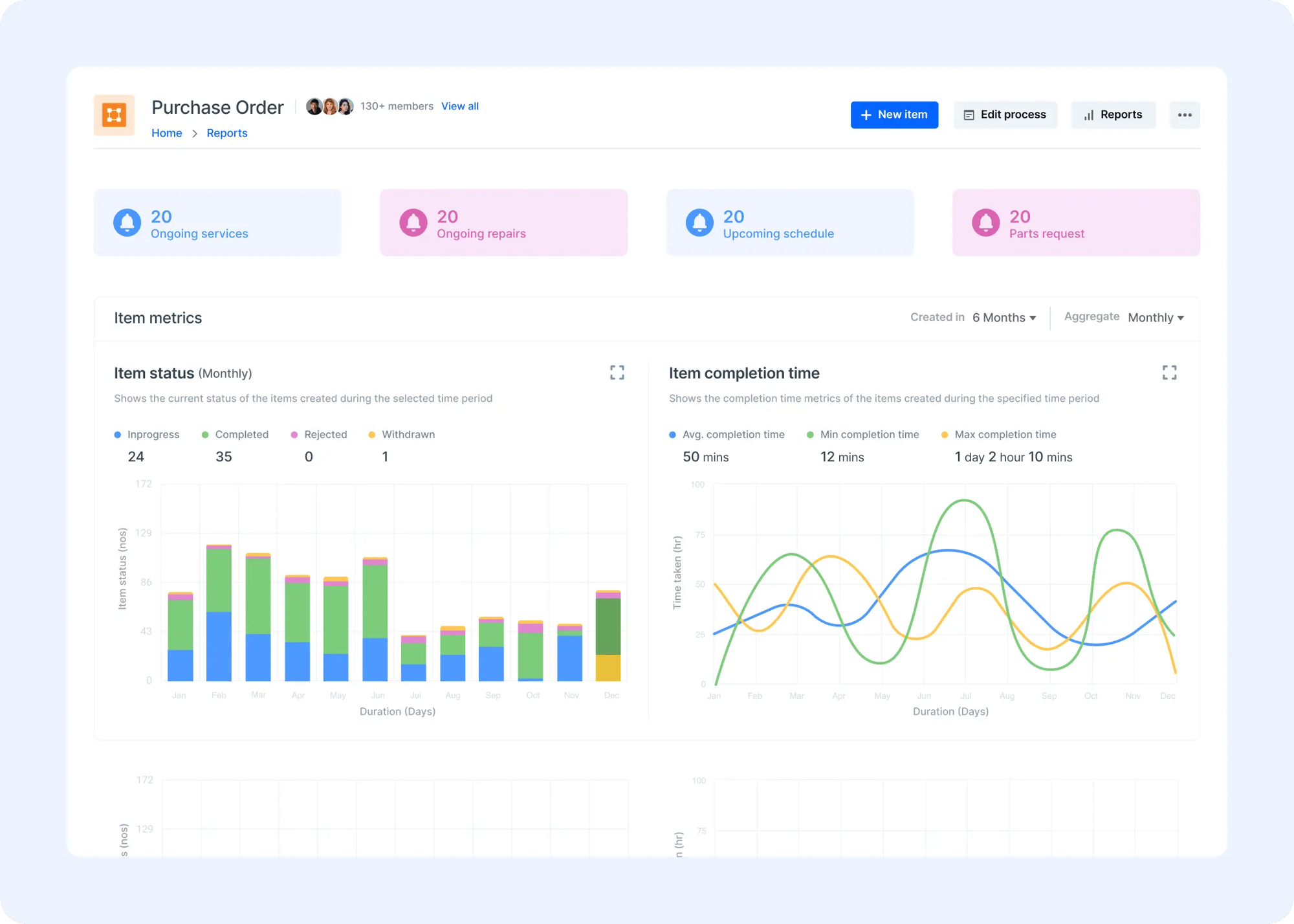

Build Comprehensive Dashboards

Gain visibility into what’s in stock, in transit, or in maintenance across different locations

A Radically Better Low-Code

Platform for Manufacturing

Extend systems

Extend the core functionality of your ERP systems

Democratize development

Enable process experts to build apps independently

Improve quickly

Make lightning-fast changes in just a few clicks

Hear From Our Happy Customers

"Kissflow has streamlined our ability to track reports and processes. This has saved us countless man-hours."

Robert Hulak Jr.

Atlas

"With Kissflow, I got used to developing processes very fast and the support given was very helpful."

Griselda Juve

Olympus

"The Kissflow team met our expectations and helped make the transition smooth. The support personnel has been very helpful and always available when needed to help us to fix issues.”

Nicholas Githinji

Ramco

“Kissflow is one of our main systems. It lets everyone have any form request that goes through multiple departments for actions.”

Madhuri Balimane

Lumen Australia